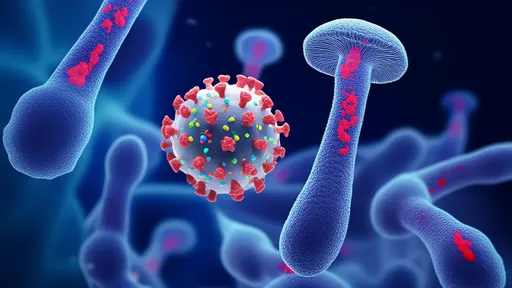

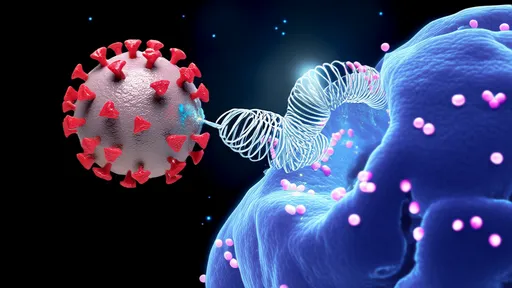

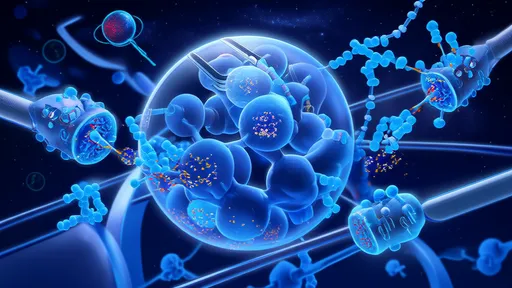

In the ever-evolving field of material science, researchers are increasingly turning to nature for inspiration. One of the most fascinating developments in recent years is the exploration of bacteriophage structures to design earthquake-resistant materials. Bacteriophages, or phages for short, are viruses that infect bacteria, and their unique architectural properties have caught the attention of engineers and scientists alike. The intricate balance of strength and flexibility in their protein shells offers a blueprint for creating synthetic materials that can withstand seismic forces.

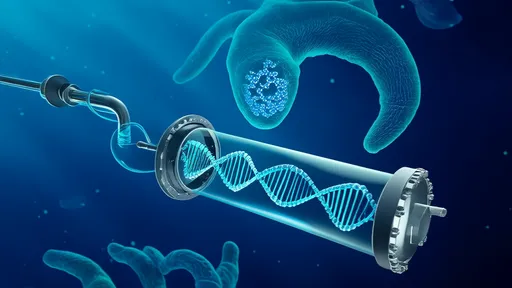

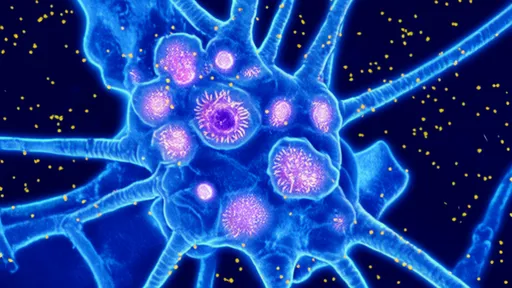

The study of bacteriophages is not new, but their potential application in structural engineering is groundbreaking. These viruses possess a remarkable ability to assemble themselves into highly stable yet dynamic structures. Their capsids, or outer protein shells, are composed of repeating subunits that interlock with precision. This modular design allows them to endure significant mechanical stress without collapsing—a property that is highly desirable in earthquake-prone regions. By mimicking these natural mechanisms, researchers hope to develop construction materials that can absorb and dissipate energy during tremors.

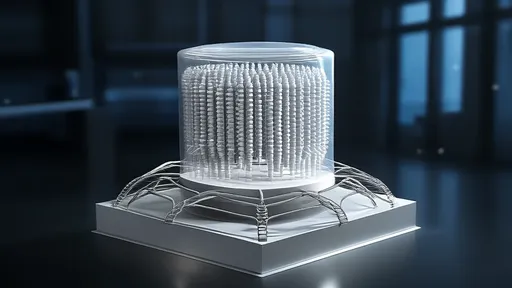

What makes bacteriophages particularly intriguing is their geometric efficiency. Their icosahedral symmetry—a shape with 20 triangular faces—distributes stress evenly across the structure. This minimizes weak points and maximizes resilience. Engineers are now experimenting with synthetic analogs that replicate this geometry at a larger scale. Early prototypes have shown promising results in laboratory tests, demonstrating enhanced durability under simulated seismic conditions. The goal is to integrate these bio-inspired materials into buildings, bridges, and other critical infrastructure.

Beyond their geometric advantages, bacteriophages also exhibit self-assembly properties that could revolutionize manufacturing processes. Traditional construction materials often require energy-intensive production methods, but phage-like structures can form spontaneously under the right conditions. This could lead to more sustainable and cost-effective solutions for earthquake-resistant design. Researchers are exploring ways to harness this self-assembly capability to create lightweight yet robust composites that could be deployed in disaster-prone areas.

The implications of this research extend far beyond earthquake mitigation. If successful, phage-inspired materials could redefine how we approach structural integrity in a variety of applications, from aerospace to biomedical devices. The interdisciplinary nature of this work—combining virology, materials science, and engineering—highlights the importance of cross-disciplinary collaboration in solving complex challenges. As climate change increases the frequency and intensity of natural disasters, innovations like these could play a crucial role in safeguarding communities.

While the potential is immense, there are still hurdles to overcome. Scaling up phage-inspired designs for real-world construction poses technical and logistical challenges. Researchers must ensure that these materials are not only effective but also economically viable and environmentally friendly. Field testing will be essential to validate their performance under actual seismic conditions. Nevertheless, the progress made so far suggests that nature’s smallest architects may hold the key to building a more resilient future.

In the coming years, we can expect to see more collaborations between biologists and engineers as they refine these bio-inspired materials. The fusion of biological principles with advanced engineering techniques promises to unlock new possibilities in disaster resilience. As our understanding of bacteriophage structures deepens, so too does our ability to emulate their genius in human-made systems. This convergence of nature and technology may well herald a new era in earthquake-resistant design.

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025

By /Jul 14, 2025